In quality management, spotting the core issues is crucial. This helps in finding real solutions. Root cause analysis is all about this.

It uses many tools to find what’s really causing the problems. Some of these tools are Pareto charts, 5 Whys, fishbone diagrams, and much more. They give organizations deep insights into their problems.

Key Takeaways:

- Root cause analysis is essential for effective problem-solving in quality management.

- Methods such as Pareto charts, 5 Whys analysis, fishbone diagrams, scatter plot diagrams, and FMEA can be used to identify root causes.

- These tools help prioritize efforts, dig deeper into underlying causes, categorize and analyze potential causes, and prevent defects.

- Implementing root cause analysis techniques leads to long-term improvements in quality, efficiency, and customer satisfaction.

- Consistently addressing the root causes of problems is key to developing sustainable solutions.

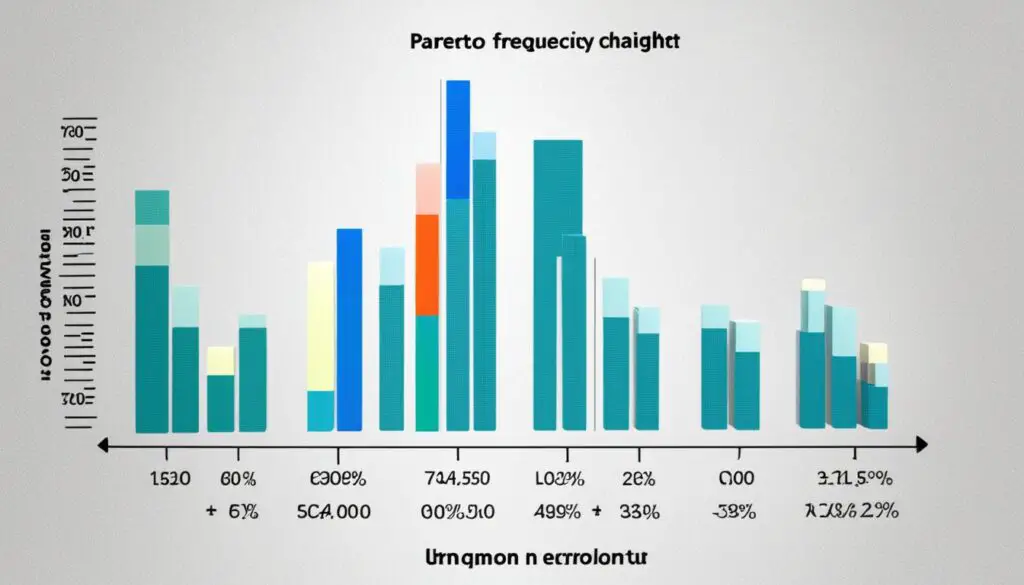

Pareto Chart: Analyzing Problem Frequency and Significance

A Pareto chart is great for digging into issues at their roots. It shows the problems’ frequency or cost and how big they are. This information helps figure out what to tackle first.

Pareto charts put problem bars in order by size. This means we see the most common issues right away. So, organizations can spend their energy where it makes the most difference.

The line on a Pareto chart tells us the total, showing problems’ overall impact. It’s a quick way to understand the big picture.

This chart follows the 80/20 rule, meaning a small part often leads to most of the results. So, fixing key issues can boost quality big time.

Using a Pareto chart focuses efforts where they matter most. It gives a roadmap for boosting quality based on real data.

Example of a Pareto Chart:

In manufacturing, a company aims to boost quality by handling top defects. The Pareto chart pointed out the main issues: wrong sizes, bad material, and bad assembly.

By fixing these top issues, which cause most of the defects, quality and satisfaction should rise.

Benefits of Using a Pareto Chart in Root Cause Analysis:

- Provides a visual representation of problem frequency and significance

- Allows organizations to prioritize efforts based on the most significant problems

- Aligns with Pareto’s law, emphasizing the impact of the vital few factors

- Offers a clear roadmap for quality improvement initiatives

- Facilitates data-driven decision-making and problem-solving

Pareto charts are powerful. They shed light on key issues, guiding actions toward what improves quality the most. It makes problem-solving smarter and more effective for lasting success.

5 Whys Analysis: Drilling Down to the Root Cause

The 5 Whys analysis helps find the real reason behind a problem. It’s about asking “why” enough times to get to the heart of an issue. This way, we can figure out the true cause and fix it. This method is great because it’s easy and works for many types of problems.

Let’s say there’s a product everyone is complaining about. The first “why” might show it doesn’t last as long as customers hoped. The second “why” could point to the low-quality parts. Keep asking and you might find the real issue is in the way suppliers are chosen. Fixing this could lead to picking better suppliers and making a product that people like more.

The 5 Whys isn’t always the only tool we use. Sometimes, we mix it with other ways of looking at problems. This makes our understanding deeper. Plus, it helps decide which problems need fixing the most first.

The Power of Combining Techniques

By using the 5 Whys with tools like Pareto charts, we can do more. We can find the main issue and know how to fix it best. Combining these methods is a strong way to solve problems and get better at what we do.

| Benefits of 5 Whys Analysis: | Limitations of 5 Whys Analysis: |

|---|---|

|

|

Fishbone Diagram: Categorizing and Analyzing Possible Causes

A fishbone diagram, known as a cause-and-effect or Ishikawa diagram, helps analyze problems. It looks like a fish skeleton, with the problem at the head. Different possible causes branch out from there.

Causes group into categories, like the 6Ms: Man, Machine, Methods, Materials, Measurement, and Mother Nature. This helps organizations check each cause carefully. By doing this, they wisely choose what to focus on for fixing the issue.

Think of a fishbone diagram as a roadmap that guides you in identifying and understanding the underlying causes of a problem. It allows you to break down a complex issue into its contributing factors, making it easier to identify where to focus your efforts for improvement.

The fishbone diagram shows how different causes are linked to the problem. It gives a full view and points out the biggest influences. This way, you can understand the problem fully and examine all important causes together.

- Man: Look at how people’s skills, training, and actions can be part of the problem.

- Machine: Check how tools, equipment, or technology play into the issue.

- Methods: Examine if ways of doing things or guidelines are causing the problem.

- Materials: Think about whether the quality or type of materials used is an issue.

- Measurement: Consider how data collection and tracking might be affecting the problem.

- Mother Nature (environment): Reflect on how outside factors like weather or climate could be involved.

After careful review, you can spot the main causes that need fixing. By tackling these main causes, real and lasting improvements are possible.

Failure Mode and Effects Analysis (FMEA): Identifying and Preventing Defects

Failure Mode and Effects Analysis (FMEA) helps find possible product and process issues. It looks at failure modes, their effects, and causes. This way, problems can be stopped before they happen, making things better.

During planning, FMEA looks at risks carefully. It checks how bad, likely, and easy to find problems are. This makes it clear which issues to focus on first. Then, efforts can be directed where they’re most needed to stop big troubles.

FMEA digs into flaws and what harm they could do. It makes risks clear and plans to handle them get clear. This means choosing actions that stop problems before they affect work or products.

Anticipating failures, FMEA improves products and ways of working. It helps manage risks well, makes stuff better, and uses resources well. By finding and fixing flaws’ main causes, it stops problems from starting in the first place.

Benefits of Failure Mode and Effects Analysis (FMEA)

- Early Detection: FMEA helps find and fix problems early, saving time and money.

- Proactive Risk Management: It lets organizations handle risks before they become big issues.

- Continuous Improvement: FMEA makes products and processes better over time by learning from failures.

- Cost Reduction: Fixing problems early saves money on fixes and keeps customers happy.

- Enhanced Customer Confidence: It shows a company cares about quality, making customers trust them more.

To sum up, FMEA is key to finding and stopping defects in products and ways of working. It spots what can go wrong and how to stop it. This leads to better quality and continuous growth. FMEA is critical in stopping issues before they start, ensuring a high level of success and customer joy.

Conclusion: Effective Root Cause Analysis for Sustainable Solutions

Root cause analysis is key in finding and solving problems. It uses tools like Pareto charts and 5 Whys to get at problems’ core. This allows organizations to find and fix issues for good. It helps them focus and dig into what’s really causing problems. By doing this, they can stop problems from happening again.

This method helps prevent defects and improve quality and customer satisfaction. By using these techniques, long-term improvements are very much possible.

Root cause analysis gives us a clear way to solve problems. It lets us get to the real causes, not just the symptoms. This way, we can stop problems from coming back.

This saves time and money in the end. It also lets us spot and stop problems before they grow.

To make this work, continual improvement and a love for learning are necessary. Everyone involved needs to work together and share feedback often. This way, not only are immediate issues fixed, but a path for continuous betterment is laid. This method is vital for offering top-tier products and services. It helps us serve our customers better and achieve success.

FAQ

What is root cause analysis?

Root cause analysis is key in solving problems in quality management. It finds and fixes the main causes of issues. This helps to really solve them.

What methods can be used for root cause analysis?

Various methods are available for root cause analysis. These include Pareto charts, 5 Whys, fishbone diagrams, and more. Each helps to delve into problems deeply to find the real cause.

What is a Pareto chart?

A Pareto chart is a unique way to do root cause analysis. It shows the importance of different issues. This helps to focus on what matters most first.

How does the 5 Whys analysis work?

The 5 Whys analysis is a straightforward way to get to the root of a problem. By asking “why” multiple times, you can peel away layers. This uncovers the true cause step by step.

What is a fishbone diagram?

A fishbone diagram stands out as a tool in understanding problems. It shows how different causes can lead to one big issue. The setup looks like a fish’s skeleton, hence the name.

What is Failure Mode and Effects Analysis (FMEA) used for?

Failure Mode and Effects Analysis (FMEA) finds possible problems in products or processes. It looks at how failures might happen, their effects, and what causes them. This is key to preventing issues before they occur.

Why is root cause analysis important?

Root cause analysis is vital in quality management and solving problems. It helps organizations to look deeply into problems. This way, they can find lasting solutions and prevent issues in the future. Different tools and methods make this process effective.